- Origin: Mainland China

- Certification: CE

- Applicable Industries: Manufacturing Plant

- Showroom Location: None

- Condition: New

- Product Type: Diaper Machine

- Processing Type: Laminating Machine

- Place of Origin: Henan, China

- Brand Name: YG/OEM

- Voltage: 380V

- Power: 350KW

- Dimension(L*W*H): 40000*4000*3000mm

- Weight: 40000 kg

- Warranty: 2 years

- Production Capacity: 250 pcs/min

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Marketing Type: New Product 2021

- Warranty of core components: 2 years

- Core Components: PLC, Engine, Motor, Bearing, Gearbox

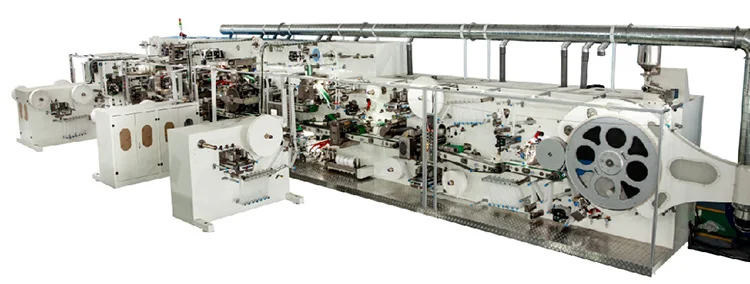

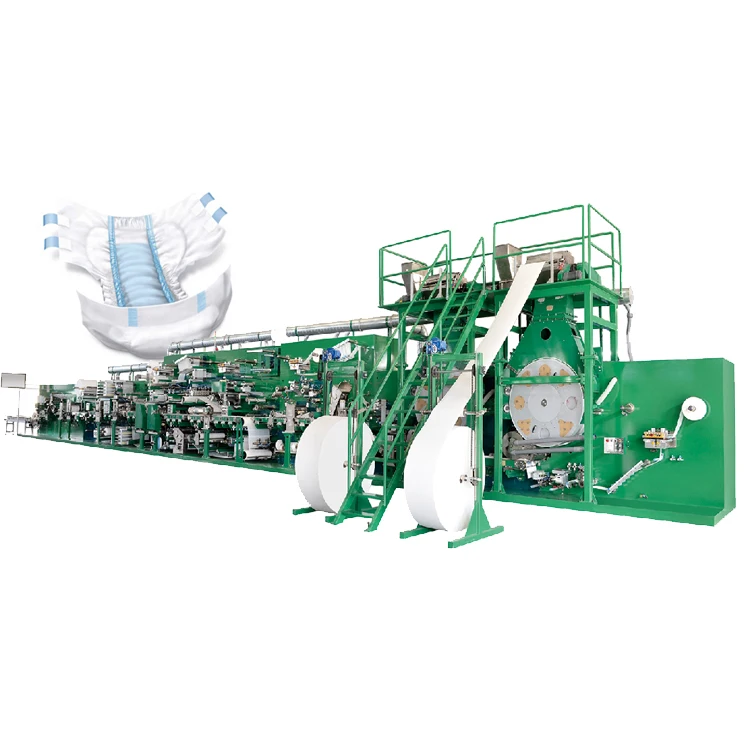

- Product Name: Baby diaper production line

- Name: Automatic Baby Diaper Pants Making Machine

- Raw Material: Wood Pulp/PE Film/Nonwoven/SAP

- Finished Products: Baby Diaper

- Product Size: NB/S/M/L/XL

- Motor: Full servo motor

- Application: Full Servo Adult Diaper Production Line Adult Diaper Making Machine

- Produt Size: M: 680x650 L: 800x650 XL: 950x760

- Pass Percentage: 99%

- Local Service Location: None

- Certification: ce

PLEASE NOTE:

1.The price only for reference, the specific cost based on your requirements and the destination port, please contact us for more product details and quotations

2.We ship you by sea !!!

3.Door to door please leave message or whatsapp or email for price !!!

High Quality Full Servo Automatic Baby Diaper Production Line

Products Description

The baby diaper production line includes mainframe, Gluing machine, packaging system and other supporting equipment, including air compressor, visual inspection system and metal detector.

|

Product Name

|

Baby / adult diaper making machine

|

|

Designed Production Speed

|

600 Pieces/Min

|

|

Stable Production Speed

|

500 Pieces/Min

|

|

Material

|

100% Polypropylene

|

|

Use

|

Baby diapers, Adult incontinence

|

|

Machine Voltage

|

380V, 50Hz, Three-Phase Five-Wire

|

|

Machine Power

|

350Kw~400Kw

|

|

Colors

|

Any color available

|

|

Width

|

According to your requirement

|

|

Payment

|

T/T, Alibaba Pay

|

|

Sample

|

Free

|

|

Packaged

|

PP bag+PE wrapping film, According to your requirement

|

|

Machine Size

|

30*7*3.5m(L*W*H) (Can Be Customized)

|

|

Machine Weight

|

50T

|

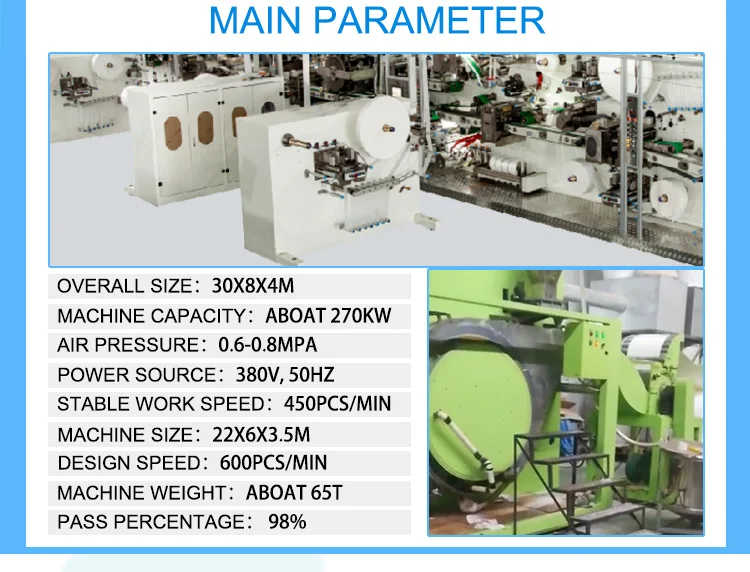

Product Paramenters

|

I shape baby diaper production

|

|

|

|

Overall Size

|

30*6*4m

|

|

|

Machine Size

|

22*2*3.5m

|

|

|

Design Speed

|

600pcs/min

|

|

|

Stable work speed

|

450-500pcs/min

|

|

|

Pass percentage

|

98%

|

|

|

Power source

|

380V,50HZ

|

|

|

Machine capacity

|

about 260kw

|

|

|

Air pressure

|

0.6-0.8Mpa

|

|

|

Machine weight

|

About 60T

|

|

|

Configuration

|

|

|

|

Product size

|

S: 390x280 M: 450x320 L: 500x320 XL: 525x330

|

|

|

Safety system

|

It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer.

|

|

|

Control system

|

PLC control system,Operating on the touch screen,Configure HDTV monitor

|

|

|

Materials corrective system

|

Germany BST automatic web guide system (optional).

|

|

|

Drive system

|

Three-axis or full servo

|

|

|

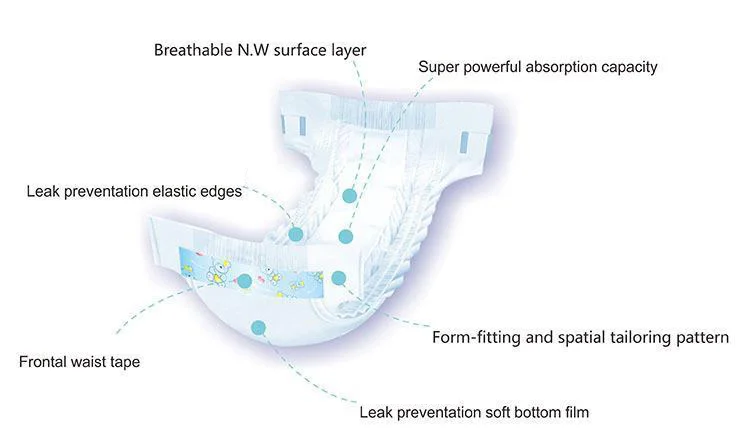

Product structure

|

Up&Down Tissue, Fluff core(mix with SAP), ADL, Backsheet, Front tape, Topsheet, Leg cuff N.W., Side Tape, Waistband.

|

|

|

Tension system

|

Up&Down Tissue ADL, Back sheet, Top sheet, Cuff N. W., are adopt A&B shaft active unwinding by inverter motor.

|

|

|

Packing Way

|

Equipped with the stacker at the request of client.

|

|

|

T shape baby diaper production

|

|

|

|

Product size

|

380x280 420x320 480x320 520x340

|

|

|

Safety system

|

Safety guard installed at the operating side, with security identifier, emergency stop switch at per segment, Driven side is

equipped with the radiator system and safety wire. |

|

|

Control system

|

PLC control system,Operating on the touch screen,Configure HDTV monitor

|

|

|

Materials corrective system

|

Germany BST automatic web guide system (optional).

|

|

|

Drive system

|

Full servo drive, digital size change, ensure, run synchronized at full process. The frontal tape and back sheet using servo

positioning cutting to ensure pattern consistent with the phase. |

|

|

Product structure

|

Top(bottom) tissue paper,sap core,ADL,hydrophobic NW(leg cuff),topsheet NW,PE film,spandex,frontal tape,elastic

nonwoven(zero-waste),S cut |

|

|

Tension system

|

Tissue paper, cotton core (SAP), Top sheet nonwoven, ADL,PE film,back&wing release paper,packing film A&B shaft unwinding by

Inverter motor |

|

|

Packing Way

|

Auto stacker as customized design (one push two exit.).

|

|

Details Images

Product packaging

High Quality Full Servo Automatic Baby Diaper Production Line

1. Packaging:

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

Company Profile

Why Choose Us

1.We have more than15 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

Contact Us

Avaliações

Ainda não existem avaliações.